Structures and Properties of β-nucleated Polypropylene/Polyamide 6 Blends

Keywords: polypropylene, beta-nucleation, polyamide, crystallization and melting behaviors, thermal and mechanical property, DSC, XRD, POM, SEM, TG, ARES, GPC;

Isotactic polypropylene (PP) is a polymorphic material with three known possible crystal forms, namely, monoclinic (α-crystal), trigonal (β-crystal), and triclinic (γ-crystal). Mre attentions were dedicated to β-crystal due to its excellent thermal and mechanical properties, such as higher thermal deformation temperature, improved elongation at break and impact strength. However, high content of β-crystal can only be obtained under special crystallization conditions such as introduction of a β-nucleating agent thanks to its lower stability compared to α-crystal. Moreover, the yield strength and elastic modulus of β-PP are lower than those of α-PP.

Isotactic polypropylene (PP) is a polymorphic material with three known possible crystal forms, namely, monoclinic (α-crystal), trigonal (β-crystal), and triclinic (γ-crystal). Mre attentions were dedicated to β-crystal due to its excellent thermal and mechanical properties, such as higher thermal deformation temperature, improved elongation at break and impact strength. However, high content of β-crystal can only be obtained under special crystallization conditions such as introduction of a β-nucleating agent thanks to its lower stability compared to α-crystal. Moreover, the yield strength and elastic modulus of β-PP are lower than those of α-PP.

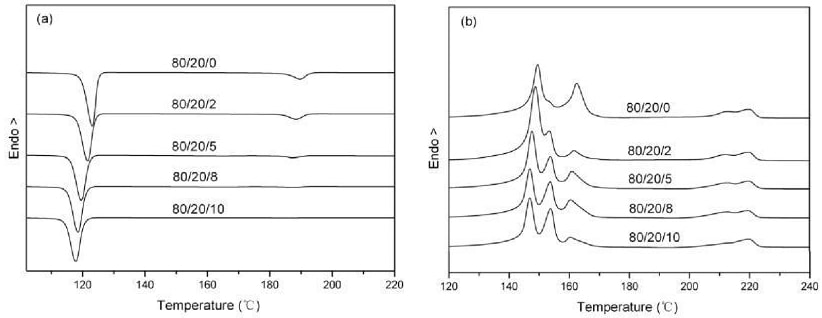

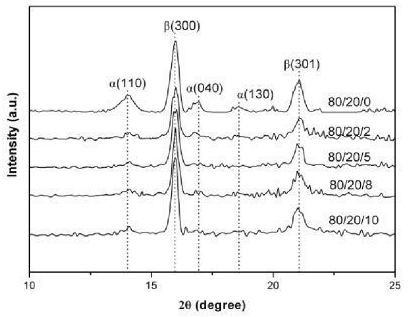

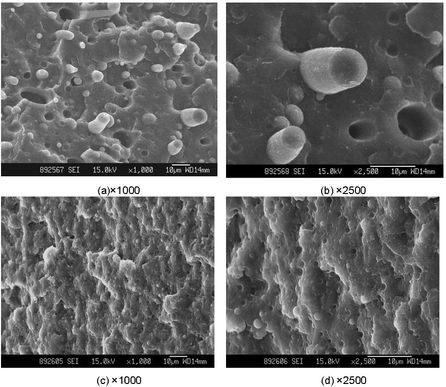

The project aims to prepare β-PP/PA blends with high β-crystal content and excellent performance: high toughness, yield strength and elastic modulus. Herein, we developed a novel nano-CaCO3 supported β-nucleating agent (NA) (patent in China) and firstly referred to the term “supporting nucleating agent”, with high efficiency of β-nucleating but low cost. Then β-nucleated PP with high content of β-crystal (up to 99%) was prepared by introducing such nano-CaCO3 supported NA. However, PP matrix crystallized predominantly in α-crystal in the presence of PA due to its α-nucleating ability and the polar interaction between PA and β-nucleating agent (Fig.3 and Fig 4.). After evaluation of parameters (including NA, PA content, the compatibilizer type and content, blending temperature, times etc.) influencing the β-crystal content in β-PP/PA blends, we developed a special approach (patent in China) to prepare blends containing high content of β-crystal. Then we prepared β-nucleated PP blends with series of polyamide (PA) such as PA6, PA66, PA1010, with various group of -CH2- and polarity with or without compatibilizer, aiming to prepare excellent materials (high toughness, yield strength and elastic modulus) with combination advantages of both β-PP and polyamide as well as to investigate relationship between the structure and mechanical properties.

Featured References

1. Crystallization and melting behavior of beta-nucleated isotactic polypropylene/polyamide 6 blends with maleic anhydride grafted polyethylene-

vinyl acetate as a compatibilizer.

Yang Z, Mai K.

Thermochim Acta 2010; 511(1-2): 152-158. PDF

2. Melting characteristic and β-crystal content of β-nucleated polypropylene/polyamide 6 alloys prepared by different compounding methods.

Yang Z, Chen C, Liang D, Zhang Z, Mai K.

Polym Int 2009; 58(12): 1366-1372. PDF

3. Effects of polyamide 6 on the crystallization and melting behavior of β-nulceated polypropylene.

Yang Z, Zhang Z, Tao Y, Mai K.

Eur Polym J 2008; 44(11): 3754-3763. PDF

4. Crystallization behavior and melting characteristics of PP nucleated by a novel supported β-nucleating agent.

Zhang Z, Wang C, Yang Z, Chen C, Mai K.

Polymer 2008; 49(23): 5137-5145. PDF

vinyl acetate as a compatibilizer.

Yang Z, Mai K.

Thermochim Acta 2010; 511(1-2): 152-158. PDF

2. Melting characteristic and β-crystal content of β-nucleated polypropylene/polyamide 6 alloys prepared by different compounding methods.

Yang Z, Chen C, Liang D, Zhang Z, Mai K.

Polym Int 2009; 58(12): 1366-1372. PDF

3. Effects of polyamide 6 on the crystallization and melting behavior of β-nulceated polypropylene.

Yang Z, Zhang Z, Tao Y, Mai K.

Eur Polym J 2008; 44(11): 3754-3763. PDF

4. Crystallization behavior and melting characteristics of PP nucleated by a novel supported β-nucleating agent.

Zhang Z, Wang C, Yang Z, Chen C, Mai K.

Polymer 2008; 49(23): 5137-5145. PDF